Uncompromising Flexibility for Machine Tools

WITH CAMWORKS MULTIAXIS MACHINING SOFTWARE, TAKE ADVANTAGE OF 4/5 AXIS MACHINES FOR GREATER PRODUCTIVITY AND QUALITY FROM YOUR CNC MACHINE

Equipment FlexibilityEquipment FlexibilWith CAMWorks Multiaxis Machining software, take advantage of 4/5 Axis machines for greater productivity and quality from your CNC Machine.ty See CAMWorks Live! |

CAMWorks Multiaxis Milling software for programming multi-axis CNC machines allows for a wide variety of uses and applications. It is useful for both shops and manufacturing facilities that require flexibility in their software and machine tools.

Multiple Multi-Axis modules for your requirements:*

- 3 Axis Mill with undercutting - For 3 axis machining requiring undercutting.

- 4 Axis Mill - For up to 4 axis simultaneous machining

- 5 Axis Mill - For up to 5 axis simultaneous machining

*All Multiaxis modules include 2.5 Axis Mill and 3 Axis Mill.

Machine Complex Parts

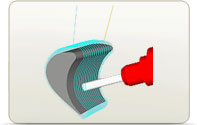

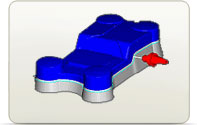

CAMWorks 4/5 Axis simultaneous machining programming software allows the user to create toolpaths across complex shapes that could not be machined on 3 Axis machines. This includes high-performance automotive port finishing, impellers, turbine blades, cutting tools, 5 Axis trimming, and undercut machining in mold and die making. CAMWorks 4 Axis simultaneous machining is designed for complex rotary applications such as camshafts, extrusion screws and blades.

Reduce Cycle Time - Improve Surface Finish - Extend Tool Life

- Shorter cutting tools can be used since the tool can be tilted to adjust the angle between the cutter and the part. The increased rigidity of shorter tools allows you to take advantage of the high-speed options in CAMWorks to machine at higher speeds with no loss in accuracy. The result is better surface quality and reduced finishing time.

- Generating 5 Axis swarf toolpaths instead of traditional 3 Axis toolpaths can result in fewer cut passes and improved surface finish.

- By optimizing the angle between the tool and the surface, it is possible to achieve a constant chip load and a high feedrate at the contact point. The result is improved surface finish and extended tool life.

- Parts that previously required multiple setups can be machined in a single setup with simultaneous control of the rotary axis. In addition to saving time, this also cuts down on mistakes that might be made during multiple setups.

Highlights

CAMWorks Multiaxis Machining provides a powerful set of features and cutting strategies to meet the machining requirements of diverse applications.

- Support for multiple tool types including flat, ball, hog nose, tapered and undercut tools such as lollipop and keyway.

- Cutting strategies for swarf cutting, profile contouring, engraving, grooving and machining deep corners and cavities.

- The tool orientation while in contact with surfaces is completely user-controlled. Options include the ability to define tool orientation relative to the surface normal. To get a good finish with a 5 Axis machine, the tool should have a specific angle to the surface. This tilt angle can be fixed, a variable angle based on the current normal vector of the surface or user-defined from points, lines or curves.

- Collision detection looks at each toolpath and the surfaces to decide if the tool tip, tool shaft or holder is colliding. The check is done at each calculated tool position. Groups of surfaces can be defined, each with its own avoidance strategy.

- Roughing options include multiple cuts normal to the surface, multiple cut depths along the tool axis, full 5 Axis plunge roughing and adaptive roughing.

- User-defined limits for the machining area and tool angles on several planes for increased flexibility.

- A lag angle can be set between the end of a flat or hog nose tool and the surface, which results in a face milling condition that reduces the number of cuts in shallow areas.

- Undercut areas can be machined using 3, 4 or 5 Axis strategies.

- Rest machining options determine if CAMWorks generates toolpaths to remove remaining material based on an STL file or a calculated work-in-process (WIP).

- Options to take advantage of an existing stock geometry to minimize air cuts during roughing operations.

- User-defined options determine how CAMWorks handles gaps: gaps in surfaces can be ignored and machined without retracting the tool, the tool can be moved back to the rapid plane and skip the gap or the tool can follow other surfaces.

- Numerous options provide simple and easy trimming of vacuum-formed or fiber reinforced plastic parts.

- Multiaxis laser toolpaths can be created to trim sheet material in difficult to reach areas, for pre-production runs where stampings require trimming, or when single set up trimming is required for production speed.

- Area roughing options can be set for impeller and blisk floor finishing and roughing, and for slots on cylinders.

- A user-defined area can be defined to contain the toolpath.

- Toolpaths can be generated as separate threads and in separate processes. Multiple toolpaths will generate simultaneously and at the same time the user can continue working in other areas or on other CAM models.

- Toolpaths can be copied and rotated to create full rotation symmetric operations (for example, impeller machining).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CP-Carrillo: A CAMWorks Success Story

“CAMWorks was the only tool we found out there that could meet all our demands and their flexible approach on APIs really helped us move forward on this initiative to develop an Enterprise Business process that linked the order taking system with the design and manufacturing processes.” - Karl Ramm, CP-Carrillo

Since its founding in 1998, CP-Carrillo (Irvine, CA) has established itself as a leader in developing and manufacturing pistons for high-performance race vehicles and the aftermarket, as well as for vintage cars, motorcycles, and the marine and aerospace industries.